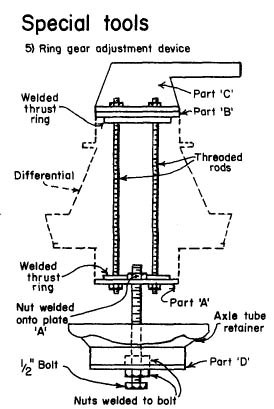

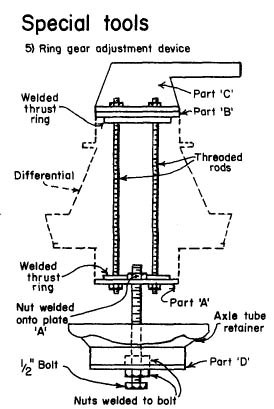

5) Ring gear adjustment device Get one axle tube retainer - you'll have to cut the axle tube in half (from a junker) to got the retainer. Use one

that's in good shape.

2) One piece of steel 1/4" thick, 2" wide and 31/2" long - cut or grind it to pattern "D" (see diag.) then drill a 9/16" hole in the center of the plate.

3) One 1/2" bolt, 5" long, got one that is threaded down to the head, or thread it yourself- Also got 3 nuts for the bolt.

4)Spin one of the nuts onto the bolt until it is approx. 1/4" away fron the bolt head. Insert the bolt through the hole in the center of plate "D". Spin the other nut onto the bolt until it is just thrust touching plate "D" Now you have sandwiched plate "D" between thenuts on the bolt. Have the nuts loose enough so that the plate turns freely between them. Now, tack weld the two nuts in place - or use loctite so it won't move. The bolt must turn easily in the plate.

5) Weld this Plate onto the axle tube retainer so that the bolt is going toward the tranaxle. (See diag.)

6) Get two pieces of steel 3/16" or 1/4" thick, 1 3/4" wide and 3" long. Cut or grind these pieces to pattern A and B. Both will be the same except A, which has a 9/16" hole drilled in the center. B does not.

7) Tack weld or braze the remaining 1/2" nut exactly centered over the 9/16" center hole of plate A.

8) Obtain two differential side gear thrust rings - grind off the indexing lobes so they turn freely inside the differential.

9)Tack or braze one of the thrust rings onto plate A. Center this ring as closely

as possible and weld ONLY on the inside edge of the ring.

10)Weld the other ring onto plate B in the manner.

11)Get a piece of 2" angle iron, 41/2" long. Cut it to drawing C, drill in the two

3/8"holes, then tack weld or braze a flat piece of steel on the top edge at the

center line. This piece must be parallel to the base as it will be the tab that the dial

indicator stem will ride on for measuring ring gear side movemnt. Measure over 2 3/4" from the center line on the arm and mark a line. It is here that you will measure backlash with a dial indicator.

12)Use two 71/4" lengths of 5/16" threaded steel rod with nuts to bolt the asembly into the differential. (see drwng.) Assemble by starting two of the nuts onto the threaded rods. (Approx. I/2" on). Insert the two rods through part A. Then install part A onto differential on ring gear side. (You'll have to remove the spyder gears and shaft in most cases.) The thrust ring should center the plate and keep it from moving.