Special tools

Put the differential bearings into the side plates. Install the final drive side plate and gasket onto the main case and tighten all nuts. Guide the differential into the bearing in the side plate. Hold the threaded rods from falling out and install part B an the other side of the differential.

Mount the other side plate with Its bearing and gasket onto the main case and over

the differential. Install part C over the threaded rods and onto part B,

fasten into place with the two nuts. Torque the side plate nuts on each side. Install the modified axle tube retainer onto the final drive cover, at same time screw the 1/2" bolt into the center of part A. Use at least three of the retainer plate nuts to fasten the plate down.

13) If you have a magnetic adjustable base for your dial indicator (two

needed here) mounting bases can be made using 1 1/2" angle iron. Cut the

angle iron to pattern E. These bases will mount onto the side cover (where the axle

tube retainer mounts) and allow you to mount magnetic dial indicator base -

stands on them, for measuring backlash and side travel of the ring gear.

14) By turning the bolt on part D - the ring gear will be moved In or out of mesh with the pinion gear, and allow you to measure movement and backlash.

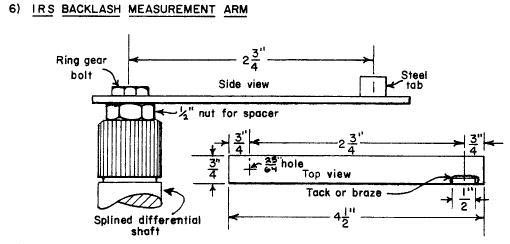

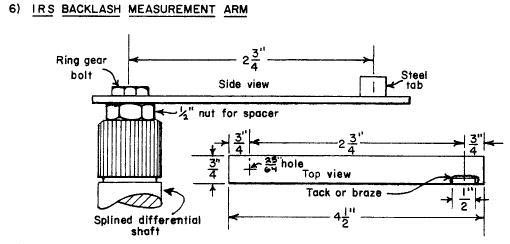

Get one piece of 3/16" x 3/4" x 4 1/4" steel. Measure in 3/4" from one end on the centerline and drill a 25/64" hole. (3/8" drill may be used, then file larger).

Get one piece of 3/16" x 3/4" x 4 1/4" steel. Measure in 3/4" from one end on the centerline and drill a 25/64" hole. (3/8" drill may be used, then file larger).

Braze or tack weld a 1/8" x 1/2" x 1/2" piece of steel at a right angle onto the edge of the arm. Center it 2 3/4" from the center of the hole. (see dwg). This tab will be a surface for the dial indicator stem to ride on. Using an old ring gear boltand a 1/2" nut for a spacer, bolt the arm onto the splined shaft of the differential. Backlash reading can be taken with the dial indicator stem resting on the steel tab of the arm. Adjustmnt is made by shim thickness between outer bearing race and the side plate.

Get one piece of 3/16" x 3/4" x 4 1/4" steel. Measure in 3/4" from one end on the centerline and drill a 25/64" hole. (3/8" drill may be used, then file larger).

Get one piece of 3/16" x 3/4" x 4 1/4" steel. Measure in 3/4" from one end on the centerline and drill a 25/64" hole. (3/8" drill may be used, then file larger).